Through Insulated cooling panels, food products and chemical products can remain with no detoriation. It especially preserve the freshness of food products. Cooling panels which have an insulation prevent air circulation between indoor and outdoor.

Insulated cooling panels especially increase the profitability of the companies working on food. Cooling panels ensure that fresh fruits, vegetables, animal products, seafood and perishable agricultural products remain fresh from the moment of production until they are presented to the customer.

Insulated Cooling Panels & Systems

Panels that have insulation are one of the indispensable devices for food companies selling perishable products. Our company, Teknotek Cooling Systems, serves its insulated cooling panels in Turkey and in the world, and enables its customers to carry out their works in the best way by also providing after-sales support. Our products are produced in accompliance with ISO 9001: 2008 quality standards.

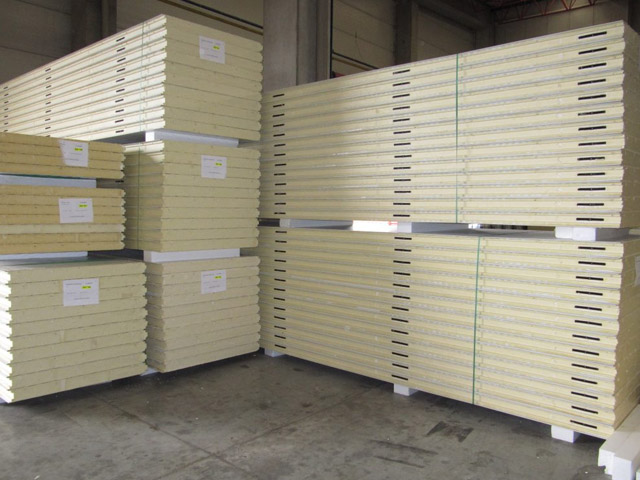

Manufacture of Insulated Cooling Panel

The most important feature of the insulated cooling panels is that they provide insulation in the best way. In order to keep the products in the best conditions, the air flow must be cut off. Air flow from outside to inside and from inside to outside can detoriate products. The cold storages produced by our company will save you a lot of energy thanks to its insulation. Cooling panels store food products between 1 and 15 degrees above freezing temperatures. Thus, water loss in food products is minimized.

Insulated Cooling Panels For Sale

The system, which ensures the food to be kept fresh for a long time, consists of the following parts according to the quality of the product to be stored:

- Panels that can be assembled and disassembled

- Doors

- Roof systems

These parts consisting of the cold storage are built according to the size of the area where the system will be installed. If a large area will be used as a cold storage, rooms are created. If you want a smaller area to be used as a cooler, a central cooling system can be installed. Some chemical products and food products are very sensitive and they should be protected under the most suitable conditions. The cold air techniques we use in the system are manufactured based on the climate of the area, how long the product can preserve its freshness, and the consumption times of the foods. Therefore, a great sensitivity is shown from the project designing to the installation of the cold storage.