The humidifier for paper production is mainly used by companies in the paper industry. It helps to store the produced paper products in the correct weather conditions.

One of the biggest problems encountered in the paper industry is keeping the produced papers in warehouses with ideal weather conditions. Therefore, the humidifier for paper production is one of the frequently preferred devices. Maintaining the ideal humidity level in the production line increases production efficiency as well as decreases the loss rate.

What Are The Uses Of Humidifier For Paper Production?

Humidifier for paper production helps paper products, whose production is very sensitive, to be stored under correct conditions and to pass through the production lines. Paper products can lose moisture inside or can absorb more moisture than necessary by being affected by the humidity level of the environment.

If paper products lose moisture during the production line, the following consequences may occur: paper products may dry and curl over time, production lines may fail, or damaged paper may adversely affect the manufacturer. On the other hand, if the environment in paper production is more humid than necessary, it can cause the paper to become wet and pulpy over time.

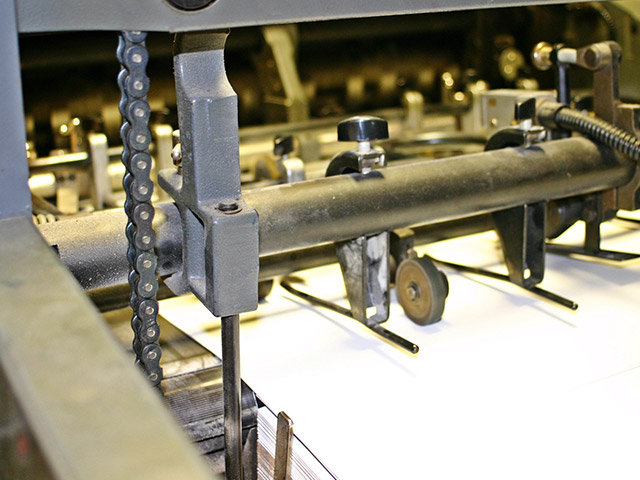

Thanks to the humidifier, the papers move through the production line at the appropriate moisture level and become ready for processing. Keeping paper products at the proper moisture level facilitates the packaging of papers. In addition, since the electrostatic charge in the environment is minimized, the papers are processed more easily.

Working Principle of Humidifier

Industrial humidification devices designed by Teknotek Cooling continuously spray water particles smaller than 10 microns into the air. The environment is always kept at the desired humidity level by pre-programming to the devices.

The water particles scattered into the air by the humidifier remain suspended in the air depending on the room temperature, so that the humidity level of the environment is kept at the desired levels. In the production line where there are no fluctuations in humidity level, fragility of paper and similar sensitive products continues to be kept at the desired level.

The oscillator in the humidifier is used to spray water particles into the air. Depending on the humidity level required in the environment, humidifiers have the capacity to moisturize from 25% to 99%.

The humidifier not only increases the efficiency of the papers passing through the production line, but also provides a clean environment for the working personnel by cleaning the ambient air and removing dust particles. In this way, both the paper products in the production line reach the desired quality and the working personnel breathe a more hygienic air.