Cold Store Panel is examined in three parts as Industrial Panel, Wall and Ceiling, Floor and Insulation. Today, the reason of high amounts of financial loss in products with expiration dates is that they are not stored accurately. The main causes of incorrect cooling are the insufficient cooling of the cold storage, insufficiencies, and poor quality materials in the devices used for cooling. As Teknotek Cooling Systems, we are at your service with our highest quality devices at the most reasonable prices.

Cold Store Panel is produced with the eccentric lock system. This system allows easy assembly and disassembly. Cold Storage Panel is produced in any desired size: width up to 114 cm, and length up to 1200 cm.

The thicknesses of the panels are produced in a wide range between 6cm and 20 cm. The panel, which can be used in all kinds of areas from process areas to deep freezer, meets all needs. Galvanized sheet, polyester coated sheet, stainless chrome nickel sheet can be used as exterior coating material for panels. Furthermore, the panels are produced with a certain amount of polyurethane filling between two sheet metal plates, so this method allows the panels to be prefabricated.

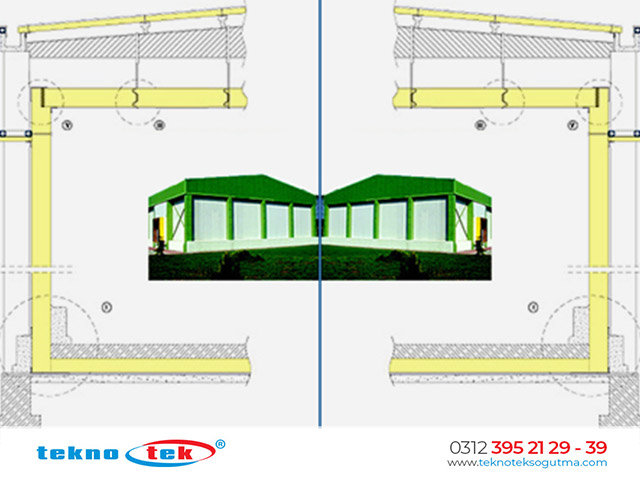

Industrial panels can be easily applied to both steel structures and reinforced concrete buildings. Thus, special solutions can be produced for the projects and all of our customers’ needs can be met. As a result of the application details, the life of the system is extended and it is ensured to be more efficient in terms of energy saving.

What is Cold Store Panels?

Prefabricated panel used in Cold Storage is filled with polyurethane. The panel is the most ideal material which gives excellent results in heat insulation in terms of its durability, ease of installation and technical features. All of our systems can be produced in ideal dimensions for different usage areas complied with the international standards such as patisseries, restaurants, supermarkets, industrial cold rooms and hospitals. It provides maximum energy saving by conducting high thermal insulation.

Industrial Panel

Cold rooms and storages are fast and practical solutions for healthy, safe and contemporary storage to keep the products to be stored fresh. Cold storages are manufactured in desired dimensions and specifications for your projects. Wall, Ceiling, and Floor Panels have 60-80-100-120-150-200 mm thickness, 1114 mm widthness and optionally length from 500 mm to 12.000 mm. 42 kg / m3 density rigid polyurethane foam is injected between the panels. Panel design is connected to each other by special eccentric lock system. This system allows the panel to be transported to different locations in store and also allows the cold storage to be expanded.

Wall & Ceiling Panel

Cold Storage Wall and Ceiling Panels reduces your energy costs thanks to the CE Certified Polyurethane filling that provides high thermal insulation. Helps maintain the quality of the products in your cold storage for a long time. The panels are produced in the same or optional surface options on both surfaces (PVC) (Polyester) (Cr-Ni) (Galvanized) depending on the demand and usage area.

Floor Panels & Insulation

Standard floor panels have the following features: Inner surface has 12 mm thickness ; Surface layers are made of original birch wood, non-slip, moisture-proof, hygienic and practical, easy to maintain, dark brown, hexagonal textured plywood with a density of 240 gr / m2; outer surface is 0.50 mm thick hot-dip galvanized steel; Uniform load bearing capacity of the panel is 3,000 kg / m2; And the panel sheet is produced optionally (PLW + Galv) (PVC + KON + Galv) (Mat Cr – Ni + KON + Galv).

If you want to be the number one in your business with the assurance of Teknotek Cooling Systems and take advantage of our Cold Store Panels services at the most reasonable prices, you can contact us immediately.